Hey! Lets Talk about your project

We’ll contact you within a couple of hours to schedule a meeting to discuss your goals.

What is Manufacturing ERP? A Complete Guide

Posted on : 15 February, 2024

Do you have ERP software integrated into your manufacturing industry?

If not, implement one because the demand for Manufacturing ERP is increasing. By doing so, you can improve the efficiency of your operations, resulting in quicker delivery times and increased productivity.

Manufacturing ERP software can notify sales management about the order's schedule, allowing them to keep the customer informed of potential risks. This also will enable sales to address any concerns or issues before they become problems.

Here, we will discuss manufacturing ERP, its benefits, and the most important six modules that you should look for in a manufacturing ERP in 2024.

Understanding of Manufacturing ERP Software

Manufacturing ERP, also known as Enterprise Resource Planning Software, facilitated a range of finance, human resources, supply chain, commerce, reporting, operations, manufacturing, and distribution activities.

It offers specialized features tailored for manufacturing, enhancing efficiency and automation across fundamental business and manufacturing operations. By facilitating daily business tasks and applications, it serves as a comprehensive platform for business management.

This ERP system is adaptable to businesses of all sizes, supporting every manufacturing entity in overseeing, automating, monitoring, collaborating, and linking every phase of their manufacturing business workflow.

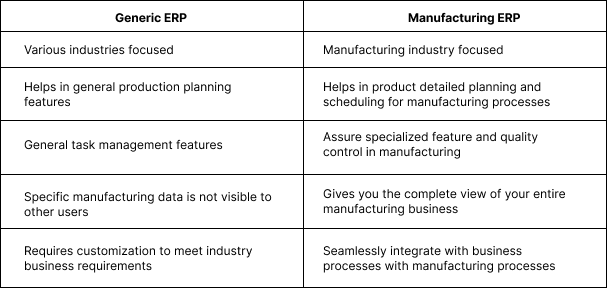

Here, you can understand the common difference between generic ERP software and manufacturing ERP software.

How Does ERP Help in the Manufacturing Industry

The worldwide ERP software market per year is more than $25 Billion, which grows 10.

Manufacturing ERP is a comprehensive approach that helps facilitate managing various aspects within a manufacturing facility. You can implement a manufacturing ERP software that provides highly advantageous results in your business operations.

- Manufacturing ERP will act as a centralized resource for inventory tracking with data analysis and setting up a good strategy.

- By using manufacturing ERP, you can assist manufacturers in creating production schedules that align with customer demand and available resources. And that helps reduce problems and improve on-time delivery.

- ERP systems provide tools for tracking and maintaining quality standards throughout manufacturing. Also, ensuring that products meet customer expectations and regulatory requirements.

- This system helps you efficiently allocate resources such as machinery, labor, and materials. Also helps you to save costs and improve production capacity.

- ERP systems help integrate various departments that provide a holistic view of the business.

- It also allows for better decision-making and greater agility in responding to changing market conditions.

Benefits of ERP For the Manufacturing Industry

The use of manufacturing ERP software can provide significant benefits to your company. Some of them are:

Easy Reporting

A manufacturing ERP system helps you avoid situations by generating reports based on your customer purchasing journey. This will help avoid the cluster of excess inventory and the out-of-stock situation. And the team can easily view their reports without any delay. Its user-friendly modules are easy to read and eliminate the risk of error.

Improving Productivity

It allows you to manage schedules, streamline financial operations, oversee sales processes, and produce real-time data. Also, reduce data errors, ensure prompt employee communication, and make data easily accessible to all. Thus, your manufacturing business is guaranteed to save time and money.

Reduced Cost

Whenever you use a manufacturing ERP system, that will help you reduce overall operational costs. And time-consuming processes are replaced with automated, streamlined processes and real-time information. You can see the inventory and warehousing costs reduction with good manufacturing ERP software.

Quality Control

ERP systems can include modules for quality control, helping manufacturers monitor and maintain high product standards. By tracking and analyzing data throughout the production process, businesses can check out the areas for improvement and take proactive measures to enhance product quality.

Inventory Management

Manufacturing ERP has inventory management, an essential benefit. ERP systems help optimize inventory levels, reduce carrying costs, and prevent stockouts or overstock situations. This ensures that materials are available when needed without tying up excess capital.

Accurate Data

Manufacturing ERP systems provide real-time data visibility to your production process. You can use this in your management to make decisions based on precise data information. It also helps control operations and improve responsiveness to changing market trends.

Key Manufacturing ERP Modules to Look For in Your Next ERP Software

Now you know what manufacturing ERP is and its benefits. So before finalizing your ERP, you have to check whether your ERP has these modules.

1. Production

A manufacturer's most important function is to produce and sell the product to the customer as per the timeline. In a manufacturing ERP, this module is specifically used to design and provide details on the production.

It includes features that help create a comprehensive list of product production functions. Also, this module ensures that your products are ready on time and available to customers when they want them delivered.

2. Purchase

Buying and selling is the primary focus of a manufacturing company. Purchase modules help manufacturers estimate and procure components based on sales orders and forecast demands.

Managers can keep track of the order until it is delivered to the receiver with the assistance of this module. It also provides notifications as required to prompt the necessary follow-up activities. Also, you can monitor and store all the transactions' records.

3. Warehouse

This warehouse module is another vital module in manufacturing ERP. It can help deliver quick ROI for organizations running their databases. That will help the warehouse team to plan more labor based on the predicted volume order.

The module supports inventory control through cycle counting processes and provides robust reporting and analytics capabilities to monitor warehouse performance and identify opportunities for improvement. The warehouse management module enhances efficiency, reduces costs, and improves customer satisfaction in manufacturing environments.

4. Sales

ERP sale modules help you provide functionalities ranging from contacting existing and potential customers to tracking sales invoices and returns. It also enables you to get insights into sales trends over specific periods and the impact of marketing campaigns via comprehensive reports.

ERP further notifies sales management, keeping them informed about the order's schedule and presenting an opportunity to alert the customer in case of potential risks. This module helps you in your manufacturing business sales forecasts and acts as feedback for product feature enhancement.

5. Finance

The finance module ERP benefits many companies by giving knowledge of their financial and future trends. You can easily create your business documents like payments, company assets, and related files and store them.

This finance module is one of the best manufacturing modules to automate financial headaches. It includes billing, management of cash, vendor payments, etc. Your accounting department can prepare financial statements with the current recognition standards while making necessary closures.

6. HR

The human resource (HR) module manages the people process associated with the large workforce. This module includes detailed employee records and saves various documents for your employees.

Also, you can track the hours your employees spend in your company and other related information regarding that. The HR module gives the manufacturing industry an advantage that helps remove a lot of data that can be saved in whatever documents you want.

Conclusion

So, in this blog, you are familiar with the manufacturing ERP and the modules that you need to take care of when selecting one.

Many manufacturers compete this time because of the increased use of these products. Selecting one is a crucial thing. Unfortunately, numerous organizations neglect to articulate anticipated benefits before choosing an ERP system, leading to process improvements that minimally impact their overall performance.

Always hire an expert ERP software development company that manufactures the most effective ERP software.

Talk to our Expert

Talk to our Expert