Hey! Lets Talk about your project

We’ll contact you within a couple of hours to schedule a meeting to discuss your goals.

How Can ERP Revolutionize the Manufacturing Industry?

Posted on : 8 April, 2024

Your business needs a manufacturing ERP to smooth all the processes in your business. And if you didn't have one until now, this blog is for you!

ERP systems are powerful software that assists in company management. Selecting the proper manufacturing ERP is what you can do for your business. In this blog, we will discuss the importance, benefits, and modules of manufacturing ERP.

Understanding Manufacturing ERP

Manufacturing ERP is called a complete software product that is designed to optimize every function of manufacturing operations. It helps integrate various functions into your business. That can include inventory management, production planning, scheduling, procurement, customer relationship management (CRM), and financial management.

Also, this manufacturing ERP software acts as a single, centralized system. ERP software provides real-time visibility and control over the entire manufacturing lifecycle.

What Are the Modules That Make a Good ERP System For Your Business

You now understand the manufacturing of ERP software. Then, we have to identify the critical modules of ERP software, which are listed below.

- Inventory Management: The inventory management module assists in optimizing stock to prevent shortages or overstocking and automating procurement.

- Production Planning and Scheduling: This particular module helps in setting up production schedules. That can be based on product demand, availability, and capacity and adjust schedules dynamically to accommodate changes in demand or resource availability.

- Quality Management: It helps establish quality control processes to ensure that products meet customer expectations. Manufacturing ERP tracks and analyzes quality metrics to identify areas for improvement. Integrating testing and inspection systems can also seamlessly improve quality assurance.

- Supply Chain Management: This functionality optimizes supply chain visibility and collaboration with suppliers and vendors. It also monitors supplier performance and effectively manages supplier relationships.

- Multi-Company Support: This feature allows businesses to ensure that financial data from various entities are seamlessly integrated. And it provides a view of the organization's finances. By managing accounting processes centrally, it promotes efficiency, accuracy, and better decisions.

- GST & VAT Compliance: The manufacturing ERP system comes equipped with GST and VAT regulations. It automates tax calculations, reporting, and filing processes. It also reduces manual tasks and minimizes errors by ensuring accurate tax management directly within the ERP solution. That helps businesses avoid penalties, maintain regulatory compliance, and optimize their tax-related operations.

- Packing and Labeling Optimization: This feature focuses on enhancing the efficiency of packaging and labeling processes within the supply chain. By automating these tasks, the ERP system streamlines operations and reduces errors. It also improves the overall professionalism and effectiveness of the supply chain workflow.

- Process Management: The ERP system offers process management features that enable businesses to manage their production process. It helps with planning and scheduling, execution, and monitoring, and it provides tools and functionalities to streamline production activities efficiently. Businesses improve productivity and maintain consistency in quality across different stages of production.

- Manage bi and semi-products: This functionality allows businesses to effectively monitor and track the utilization of by-products and semi-finished goods. By capturing data on these materials within the ERP system, companies can optimize inventory management, minimize waste, and control costs more efficiently.

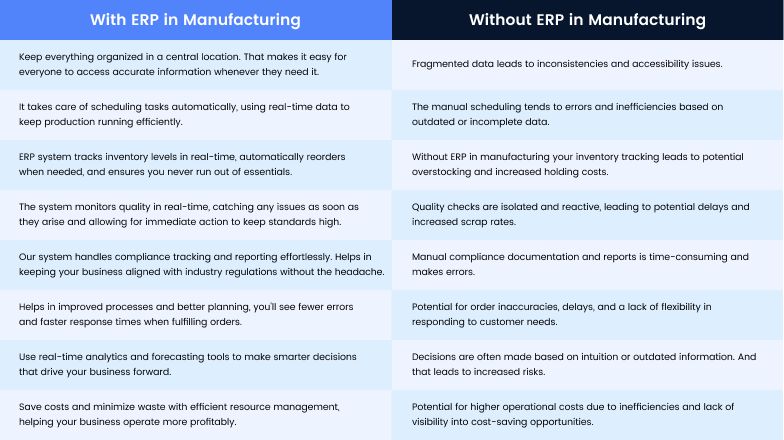

With ERP Vs Without ERP For Manufacturing Industry

Discover more about What is Manufacturing ERP? A Complete Guide by delving deeper into this essential resource.

Importance of ERP for the Manufacturing industry

Manufacturing ERP benefits your business in many ways.

- Increased business processes: Manufacturing ERP helps in business by acting as a centralized, easily accessible source for all the functions in the system. The people in any department can easily access all the information, which helps productivity. This also helps in faster coordination, teamwork, and all innovations and benefits.

- Break the Barrier of Communication: An effective manufacturing ERP helps increase the visibility of communication barriers. Everyone can easily connect with other teams, eliminating extra work, inefficiencies, and collaboration chances whenever possible. So, a perfect manufacturing ERP solves problems and gives you a strong team and smoother operations.

- Facilitates Data Analysis: ERP helps facilitate data collection and analysis. This data analysis helps you make more practical decisions. It facilitates maintenance, using machines, procurement, management of the supply chain, and more.

- Accounting easier: An integrated manufacturing ERP helps bring all the financials into one database, so the user doesn't have to waste time editing and processing data. The software will manually update all the information, so there is no time wasted. This benefit helps increase productivity and accuracy in your business.

- Improving customer satisfaction: Accurate product planning, inventory management, and streamlining process scheduling help improve customer satisfaction. A good manufacturing ERP improves productivity and product delivery, all within the perfect timing period. The quality check systems in manufacturing ERP enhance the quality of products and customer satisfaction.

When Is The Time To Implement An ERP For Your Manufacturing Business?

- If you're growing fast, it might be time for an ERP software that can keep up.

- When managing your operations starts to feel complicated, implement a manufacturing ERP system.

- If you think all your employees need coordination or are doing the same tasks repeatedly, use ERP software.

- If you cannot get the correct information when you need it, it's time for a system that organizes everything.

- A manufacturing ERP helps keep up with the rules and standards that your business faces.

- If your customers demand faster service or customized products, an ERP can help you become more agile.

- If you need a system for effectively managing your business inventory, a manufacturing ERP will help you.

- If your different departments can't communicate properly, use an ERP system.

- If you need to save the cost of your business, use an ERP that will help you.

Conclusion

Understanding the significance of a manufacturing ERP for your business is crucial. Adhering to industry standards and meeting evolving consumer demands pose ongoing challenges. Leading industry players are turning to ERP solutions to stay agile and competitive.

Hire IPIX Technologies, a trusted provider of manufacturing ERP software tailored for any business. The team helps you with all your project needs with comprehensive solutions. Schedule a free consultation call today to discover how we can tailor your manufacturing ERP system to meet your unique business requirements promptly.

Talk to our Expert

Talk to our Expert